All of the pretty features on a steel building are great, but they don’t do any good if the building does not stand the test of time. The Walters Sheer Transfer Plate (STP) column system ensures that your steel building is not going anywhere. For the more traditional, we have our standard wood column that has been tried and tested for over 30 years. It is not going anywhere. For those of you that plan of having a concrete slab poured for your job, our connection to concrete is second to none.

Our Wood Column

- We only use the best lumber. Our columns are SYP #2 lumber or better depending on the final requirements that our in-house engineers specifically designed for your steel buildings. All columns are at least 3-ply to the roof-line, not just a single 2X6 from the bottom of the truss to the roof-line, like other builders. This all makes your firm foundation permeate throughout the building.

- We use our own patented Shear Transfer Plates to hold each ply together in our columns. They are the key to the incredible load carrying capacity of our columns. Using the Shear Transfer Plate, our columns are even stronger than a solid column with the same amount of wood.

- Our Shear Transfer Plate column has been tested in both the laboratory and in the field for many years. While other builders use traditional gluelam columns, the feedback from our customers and from the lab has been clear. We would not trust the safety of our customers and their property to anything other than the Walters Shear Transfer Plate column.

- A #4 reinforcement bar is inserted through our column, and the column is partially embedded in a dry-mix concrete footing. This creates a "ball footing" on the bottom on the column, which allows for a larger column bearing and protects against uplift.

- All wood members in contact with the ground are treated to a 0.8 CCA unlike our competitors that use 0.6 CCA, which is the minimum allowed by code. This is 33% more treatment. This means that your steel building's columns are more protected against rot and insects.

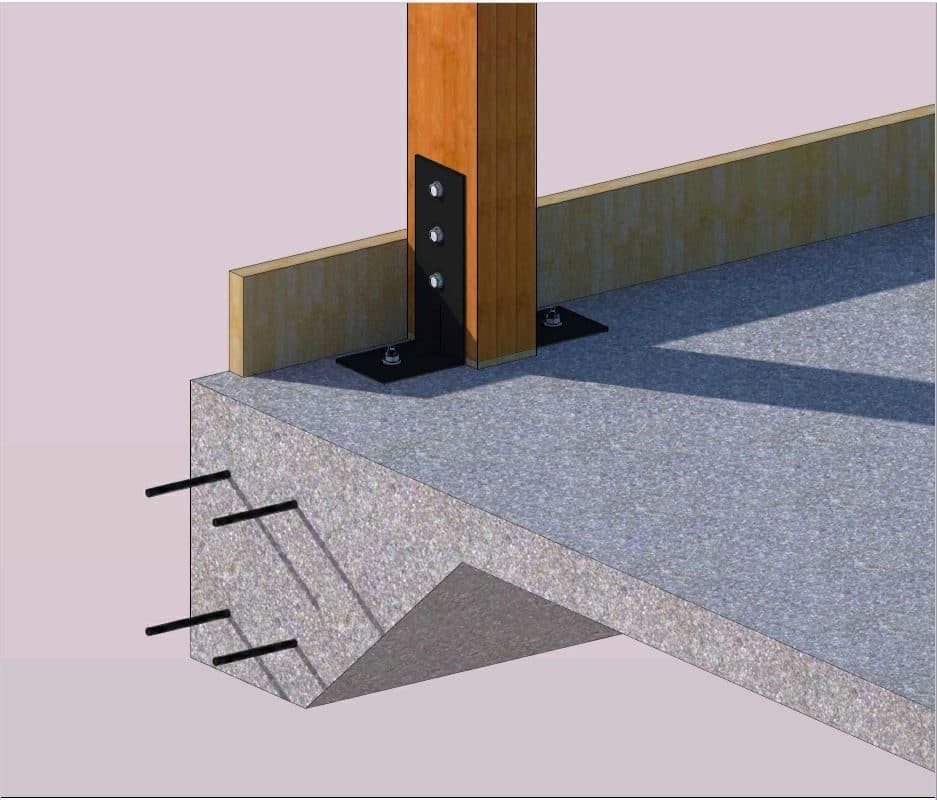

Our Connection to Concrete

In the past couple of years, building on concrete has become much more common in the post frame industry. In fact, the majority of the buildings we build start with a concrete slab. While other companies tried to figure out the cheapest way to attach to concrete, Walters decided to look at what would stand the test of time. Our attachment to concrete features:

- Two heavy L-brackets that attach both sides of the columns to concrete. Most competitors only use one bracket.

- The brackets measure 5” X 12”, making them some of the sturdiest in the post frame industry.

- The brackets measure 5” X 12”, making them some of the sturdiest in the post frame industry.

- A stiffening brace in the L-bracket in the attachment that further protects against bending.

- Three bolts attach steel to the column, unlike our competitors that generally use two.

- Thick ¼ Steel. We do not use flimsy steel in our attachments.

- Wedge anchors that pull the attachment into concrete, ensuring the connection is firm and square.