Not All Steel is Created Equally

Just as healthy skin is important because it protects us from infection, UV rays and other dangers, the steel of your pole building is crucial to its durability. Not only does great steel make the pole building look 'healthy,' but if treated properly, it can protect from rust and damage from the elements. The health of our steel is so important that we only buy American-made steel to guarantee its consistency. When you are looking to put up a pole building with steel siding, it is important to know that NOT ALL STEEL IS CREATED EQUALLY. Instead, a customer should ask their builder about the following steel characteristics prior to building:

- Rust Protection - The Difference between Galvanizing and Galvalume.

- The Gauge of the Steel or its Thickness.

- The Hardness of the Steel - Commercial Grade v. Structural Grade.

- The Panel Shape or Profile.

- Additional Features

Rust Protection

- Galvanizing (G): This involves coating the steel with zinc to prevent it from rusting.

- Galvalume (AZ): This involves coating the steel with a mixture of aluminum, zinc and silicon to prevent it from rusting.

Galvanizing

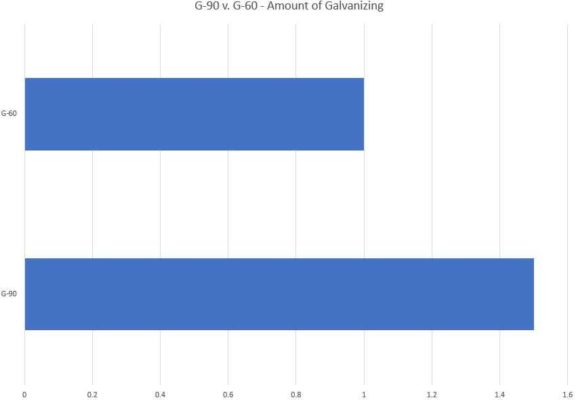

When zinc is applied to the bare steel, it is applied in different quantities (measured in ounces of coating per a square foot of steel) and given a G value (G-40, G-60, G-90, etc.) based on how much zinc is applied. As mentioned earlier, zinc is the active ingredient that protects the steel from rust. If the G value is higher, there is more zinc on the steel. This means that a G-90 is more protected than a G-60.

These G values are a bit deceiving as they refer to the total amount of galvanizing on the entire panel (front and back). Keeping this in mind, steel with a rating of G-90 has 1.5 times the amount of galvanizing as steel with a rating of G-60.

A higher the G value extends the life of your product. Also, steel with a rating of G-90 does a great job in healing itself. This means that the end cuts, field cuts and scratches are protected by the galvanizing.

Galvalume

Galvalume is also a coating that is applied to the bare steel to protect it from rusting. This coating is a combination of aluminum, zinc and silicon and is measured the same way as the galvanized coating. For instance, AZ 50, AZ 55 and AZ 60 stand for ounces of coating per square foot. So, AZ 55 has .55 ounces per square foot of steel.

We use structural steel because it performs well in hail, heavy snow and with flying debris. Our steel actually averages out to 92,000 PSI. This means that you will have a stronger structure that resists dents and keeps your pole barn looking better longer.

The Walters Way

After years of experimenting, Walters decided to use G-90 on all of its steel. Galvanizing is better at dealing with any potential scratches and damage to the steel and leaves fewer rust stains. It also performs better in animal confinement buildings, and it does not exhibit an orange peel effect that occurs in some steel treated with Galvalume.

All in all, we decided to go with what we thought was best for the customer, G-90, in order to provide you with a product that lasts longer than the competition.

Gauge: A Measure of Thickness

Gauge is a measure of the thickness of your steel.

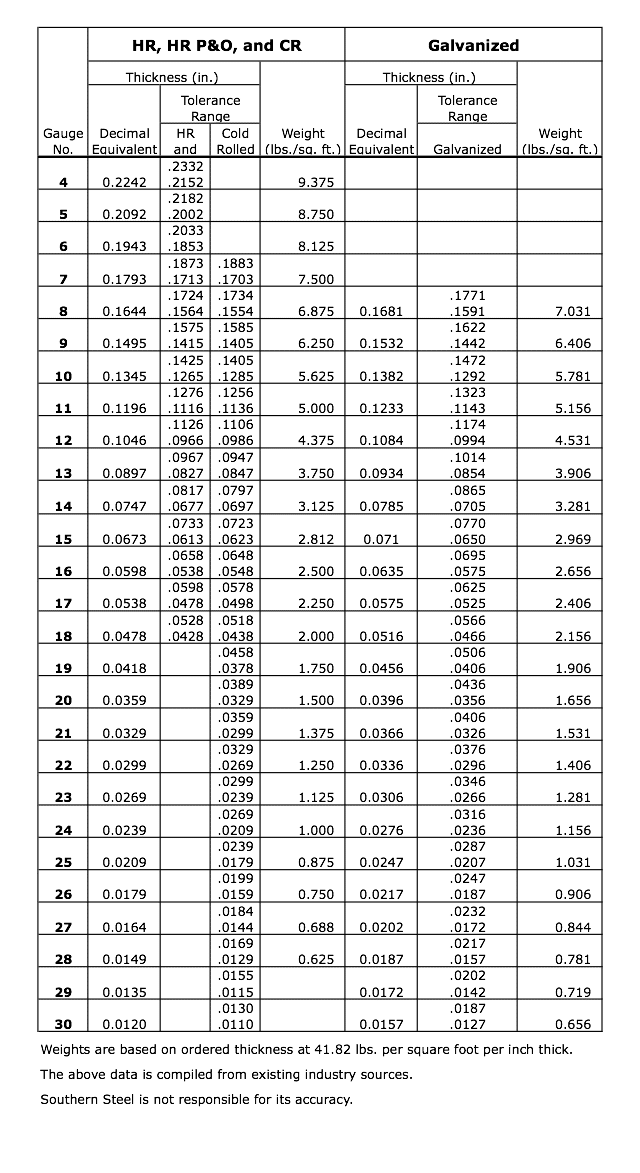

As you would imagine, thicker steel coupled with its hardness creates a stronger layer of protection for your pole building and everything inside it. When talking about gauges, it is important to know that the larger the gauge number, the thinner the steel. Measurements of gauge should be taken of the bare steel with only the galvanizing on it. Some companies even measure the steel with the paint on to say they meet a higher gauge. This is sad, but true.

The Walters Way

Most of the companies in the post frame industry offer a 29 gauge product with a minimum thickness tolerance of .0142 inches. We order our bare steel at .016 inch minimum (28 gauge). However, our steel has an average thickness of 0.017 inches. This amounts to Walters having 20.4% more steel on our pole buildings than pole buildings with a steel thickness of 0.0142 inches.

Our competitors often use .0132 inch thick bare steel and call it "29 gauge after paint". This is not the same! Our strict specifications results in our final panel thickness measuring up to .0195 inches thick with all of the coatings applied.

Hardness of Steel: Commercial Steel v. Structural Steel

The hardness of steel is measured in pounds per square inch (PSI). Generally, there are two categories when it comes to steel hardness: commercial steel and structural steel.

Commercial Steel: A soft steel that has a PSI rating in the range of 40,000.

Structural Steel: A very hard steel that has a PSI rating above 80,000.

This means that commercial steel is easier to form into panels and trim, but it also dents easier. Structural grade steel is harder; therefore, it is harder to form, requiring it to be incrementally bent at a slower rate over a longer and much more expensive set of tooling.

Once again, structural steel is more expensive, but it is nearly twice as strong as commercial steel. Structural steel can also span further and doesn't dent or sag like commercial quality steel. Structural steel also improves the overall strength of the structure, stiffing up the frame with its hardness.

The Walters Way

We use structural steel because it performs well in hail, heavy snow and with flying debris. Our steel actually averages out to 92,000 PSI. This means that you will have a stronger structure that resists dents and keeps your pole building looking better longer.

The Walters Way Goes Deeper:

Additional Benefits of Walters Steel

Panel Shape or Profile:

Walters Buildings vs. Competitors

Panel shape is also important factor to look at when choosing a builder. Walters features a 12" on center (o.c. spacing of the major rib). In our opinion, this is by far the best-looking panel on the market. The 9" o.c. spacing is very busy and the pole building does not pop. A pole building with 9" on center spacing of the major rib would have more ribs, resulting in a messier look to the pole building.

Double Syfine Groove

Walters steel features a Double Syfine Groove, which are two small grooves on the steel panels that break the water tension from rain, preventing the capillary action of the water. This prevents the water from jumping the lap rib and seeping through steel roofs.

Trim Options

Many builders in the industry have 6 different trim options. Walters has 104 different types of trims to choose from when detailing your pole building. For example, at Walters, your gable trim is designed specifically for a gable application while your corner trim is designed specifically for a corner. On top of that, we use structural steel for our trim to ensure its strength and consistency. At Walters, your pole building will be trimmed-out with extreme detail, making it more pleasing to the eye.

Paint

Walters Buildings uses BeckryTech from Becker Specialty Corporation. BeckryTech offers our customers best in class warranty protection against cracking, chalking, color fade or red rust. BeckryTech is based on a resin chemistry that is less reactive to UV light than the leading Silicone Modified Polyesters (SMP) products today.

UL 2218 Class 4 - Hail Rating

Walters Buildings is proud to announce that our 28 gauge steel panels have successfully passed the rigorous UL 2218 impact resistance test, achieving a Class 4 hail rating. Conducted by the Center for Building Innovation, this certification confirms the superior durability and resilience of our steel panels against severe hail impacts. The testing encompassed multiple locations on each panel, including the weakest points and panel overlaps, ensuring comprehensive evaluation and outstanding performance under extreme conditions. This achievement underscores our commitment to providing top-quality, weather-resistant building materials for our customers.

Summary: The Extra Cost of Steel is Well Worth It

Even though our steel costs about $0.32 per square foot more than 29 gauge, G-60 steel, you can tell from the information above that our steel is a superior product. Additionally, Walters has the option to roll steel up to 66' long, this means one continuous sheet of protection per section of your roof. When you are looking for an investment that will last a lifetime, which would you rather have?