Articles & Insights

Cost to Insulate a Pole Barn

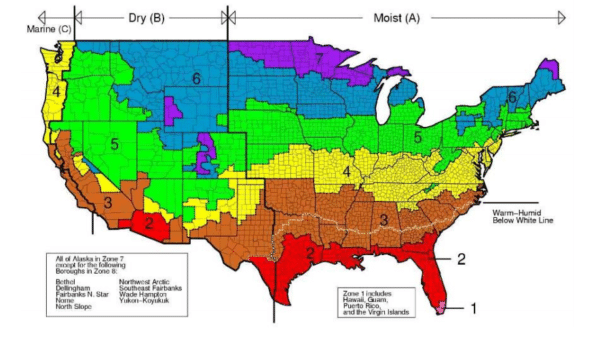

Most pole barns will cost between $5,000 and $8,000 to insulate. The costs to insulate a pole barn will depend on the size of the building, regional climate zones/energy codes and insulation type that you choose for your project. A smaller 30×40 pole barn will cost around $4,000 to insulate to code. Whereas a 40×60 pole barn will cost around $8,000 to insulate. The larger the project, the lower the cost per square foot.

The effectiveness of your insulation project will be measured by its R-Value. The R-Value is the measure of the overall resistance to heat transfer that describes how well the building conducts heat. Each insulation solution will have a different R-Value that add up to the overall effectiveness of your insulation project. The higher the R-Value, the lower the heat transfer. Fiberglass batts have an R-Value around 3.5 per inch. A polyurethane spray foam will have an R-Value around 7.0 per inch of thickness. How you choose to insulate your building will depend on specific project.

Detached Pole Barn: A detached pole barn garage, workshop, or shed for personal use will usually not be required to meet energy codes. Your decision to insulate will be driven by your level of comfort and a cost benefit analysis of the heating costs versus the insulation costs. In the Midwest, we usually see something like R-19 fiberglass batts in the walls and R-38 cellulose blown into the ceiling. This is a economical insulation solution.

Detached Pole Barn: A detached pole barn garage, workshop, or shed for personal use will usually not be required to meet energy codes. Your decision to insulate will be driven by your level of comfort and a cost benefit analysis of the heating costs versus the insulation costs. In the Midwest, we usually see something like R-19 fiberglass batts in the walls and R-38 cellulose blown into the ceiling. This is a economical insulation solution.

Commercial & Residential Buildings: A commercial building or residential garage attached to the home requires that the project meet energy codes. For these projects, it is essential that you work with a licensed contractor as the entire building must meet the correct energy requirements. This requires consideration of the heat loss through the slab/floor, walls and ceiling. An air barrier and vapor barrier will be required. There will also be fire code considerations for any commercial or attached residential buildings.

How to Insulate a Pole Barn:

Adding insulation to your pole barn barn can provide year-round comfort in a cost effective manner. But before we start to examine the different insulation options we need to address the concern of moisture in any building project. A good insulation project ensures that the building has room to “breath” to keep moisture from accumulating in your wall cavity and your attic. While this is most notable through the soffit vents and ridge vent in many buildings – the same principal applies to your wall cavities.

Choosing Insulation for your Pole Barn

- Fiberglass batts: This blanket insulation has been the most popular on the market for 55 years. While you can also purchase rolls of insulation made of wool or other fibers – fiberglass is the most common. These fiberglass rolls are fitted between the columns and can be used for the walls and ceilings. It is easy to install and can be done relatively cheaply. The R-Value of your fiberglass batt with vary depending on the thickness and the density. Energy.gov is a great resource for more information. Using a fiberglass batt with 6″ thickness will give you an R-Value around 19.

There is debate on the proper installation of fiberglass batts. If you are performing an airtight installation with Tyvek house wrap on the outside and a Visqeen vapor barrier on the inside and can keep the wall cavity sealed – you can improve the energy efficiency by putting spray foam around the top and bottom of the insulation for a perfect seal. However, this seal will keep the wall from breathing if moisture infiltrates the cavity. Most insulation contractors do not believe the minor energy savings are worth the additional cost and risk of moisture.

- Blown-In Insulation: Blown-in insulation is made up of small particles of fiber, foam or some other materials. The most common materials are cellulose, fiberglass and mineral wool. This insulation is usually blown into attic spaces as the small particles will conform to any space and create a great insulation barrier. The R-Value of blown-in insulation will increase with the thickness. Manufacturers determine the R-Value of blown insulation at its settled density – this is because as the thickness of the insulation blown-in increases, its settled density will also increase thanks to the compression from gravity. Blown-in insulation offers superior R-Value to fiberglass batts as it conforms to the space without any air gaps.

Blown-in insulation is great for attic spaces. But is not generally used for wall cavities as the weight of the blown insulation can potentially settle over time leaving air gaps in the wall. There are alternative blown-in solutions that can be used for walls. A “Blow-In-Blanket System” or “BIBS” is a specially manufactured material that will not settle.

Foam Board Insulation: Rigid form board is great insulation around the concrete slab for your pole barn. We have an entire article about Pole Barn Foundation Design and how insulation of the concrete slab affects the rest of the building’s R-Value. Foam board insulation can be used in walls and ceilings – but we do not recommend as it is not as cost effective as fiberglass batts and blown insulation.

Foam Board Insulation: Rigid form board is great insulation around the concrete slab for your pole barn. We have an entire article about Pole Barn Foundation Design and how insulation of the concrete slab affects the rest of the building’s R-Value. Foam board insulation can be used in walls and ceilings – but we do not recommend as it is not as cost effective as fiberglass batts and blown insulation.

- Spray Insulation: Spray insulation is the Rolls Royce of insulation. It costs about the same – so it is rarely used in pole barns. Spray insulation is usually made with polyurethane and can be sprayed into walls, attics and under floors to insulate. They yield a higher R-Value than other insulation and, as they fill the smallest spaces, will create an effective air barrier. Spray foam is often used in pressurized cans to fill in gaps around doors and windows during pole barn construction.

There are two types of spray insulation; closed-cell and open-cell. Closed-cell foam are high-density cells that are filled with a gas that expands the foam to fill the space around it. Open-cell foam is filled with air and is not as dense. Open-cell insulation will have a spongy texture. Closed-cell will not.

One of the advantages of spray foam is that it forms a tight air barrier which will eliminate some of the other costs associated with weathering home. However, in the pole barn application this may not be true. While you can spray foam insulation directly onto the steel panels, many spray foams have not been tested for this application and it may damage your steel panel. In addition, once a panel has had spray foam applied, it is very difficult to remove a steel panel should it need replacement. To avoid this, we recommend that Tyvek/HouseWrap be applied under the steel panels and the spray insulation be applied to the backside of the Tyvek barrier. You’ve now sealed your pole barn twice.

Steps in Insulating your Pole Barn

- HouseWrap/Tyvek: If you are working with a new construction, a HouseWrap/Tyvek on the exterior under the panels is always preferred. However, if you are working with an existing pole barn that you are insulating for the first time – having HouseWrap/Tyvek is not required.

- Install Fiberglass batt insulation in the walls: One of the great things about batt insulation is the ease in which it can be installed. The ideal installation will be HouseWrap/Tyvek on the outside, unfaced batt insulation and then a Visqeen Vapor Barrier on the inside. If you do not have HouseWrap/Tyvek on the outside – you can still insulate your building very effectively with just the unfaced batt insulation and vapor barrier. We do not use faced insulation in the walls as the paper vapor retarder can hold moisture depending on the installation.

After you have installed your insulation and vapor barrier, you can add your drywall or interior steel liner.

- Install Blown-In Insulation in the attic: Most “Do-it-Yourselfers” don’t have access to the required equipment and material to blow-in insulation. It’s worth the cost to hire a professional to blow-in insulation. Most of your energy loss with be through your ceiling and attic as the heat in your pole barn rises. You will need to install your vapor barrier and drywall/steel liner on the ceiling as you will be blowing onto the ceiling.

In the Midwest we usually get an R-Value in the attic between R-38 and R-50. Ensure that your contractor installs baffles/rafter vents to pull the airflow from your soffit vents to your ridgevent. Blocked vents will hold heat and moisture in your attic. Walters Buildings uses a 14″ heel truss on our buildings to ensure adequate space for blown-in insulation.

Pole Barns built with post-frame construction methods are a very economical building. Adding insulation can make your workshop or garage comfortable all year round. There are a lot of options for insulating a pole barn and the choice comes down to the owner’s preference. We have had customers with in-floor heat who kept their un-insulated pole barn at 45 degrees year round thanks to fans keeping the heat from rising out of the building. For a commercial project or a garage attached to a residential home, it is imperative that you work with a professional to meet your energy and fire code requirements.

While Walters Buildings does not perform insulation work – we work with highly qualified sub-contractors throughout the Midwest. If you want more information you can read about our building process, how we design our foundation or just reach out to us directly and we will have one of our experienced District Managers give you a call.

Ready to Start Your Own Custom Project?

Contact our project management team today for a personalized quote and start planning your dream building with Walters.