Build with Confidence...Build with Walters

When you are looking to build, deciding what company to build with is just as important as deciding what to build. Whether you are building a pole shed in your backyard, a steel building for your business, or a timber frame home, we want to be a partner for your building project.

At Walters Buildings, we recognize that a building purchase is a significant investment, and we don't take lightly the faith that our customers put in us to get the job done. That is why we only use the highest quality materials and the most skilled craftsmen in the industry to construct your building.

While there are lots of metal building companies out there, at Walters you will find a building experience that matches our award-winning buildings. As a general contractor or a local builder, Walters Buildings takes care of the details.

Walters Buildings started as a pole barn builder for local farmers. One building and one relationship at a time we've grown to become the premier post frame builder in the Midwest. We know how to treat you like family because we have been a family-owned business since 1958.

Mission Statement

A commitment to design, manufacture and construct a superior building with our industry leading employees and partners. In our continued pursuit of excellence, we achieve a great building experience for our customers.

AWARD

AWARD

WINNER

WINNER

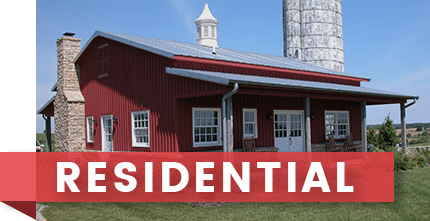

Residential

1st Place in Residential Buildings at the 2018 National Frame Building Association Awards.

At Walters Buildings, we take great pride in building the best post frame buildings in the nation. Our District Manager will work with our skilled engineering team to design your dream building. And finally, our expert crews will use only the best materials in the industry to give you a building that will last a lifetime.

But you don’t have to take our word for it. Just browse our collection of award winning projects from the National Frame Building Association.